Author: Martin Gawecki and C.-C. Jay Kuo

This work is part funded by the Pratt &Whitney Institute for Collaborative Engineering, in collaboration with Pratt & Whitney, Korean Airlines, and INHA University.

Research Problem

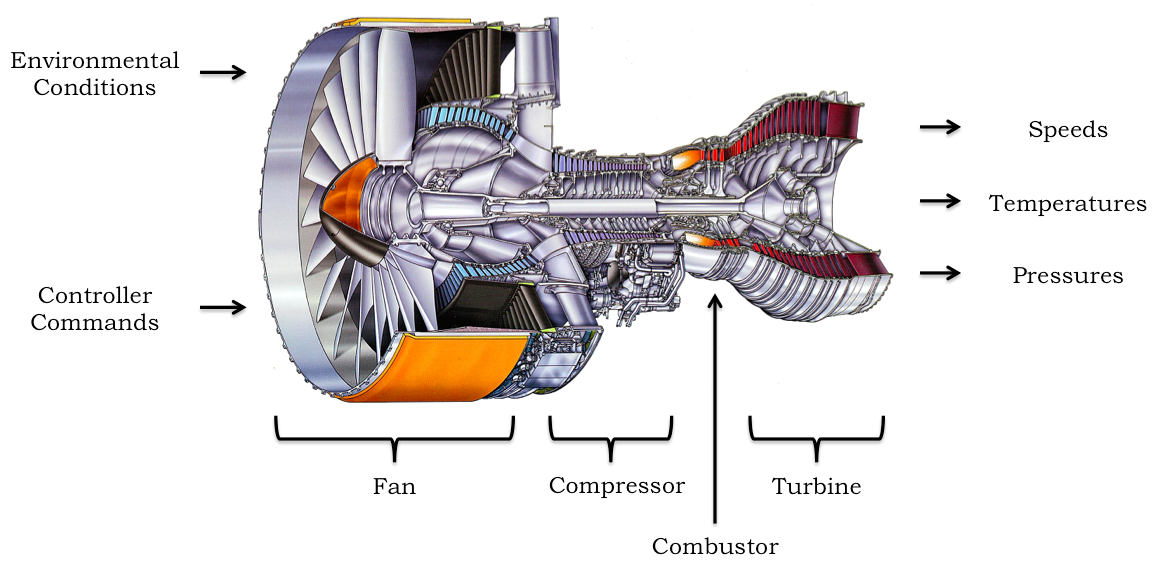

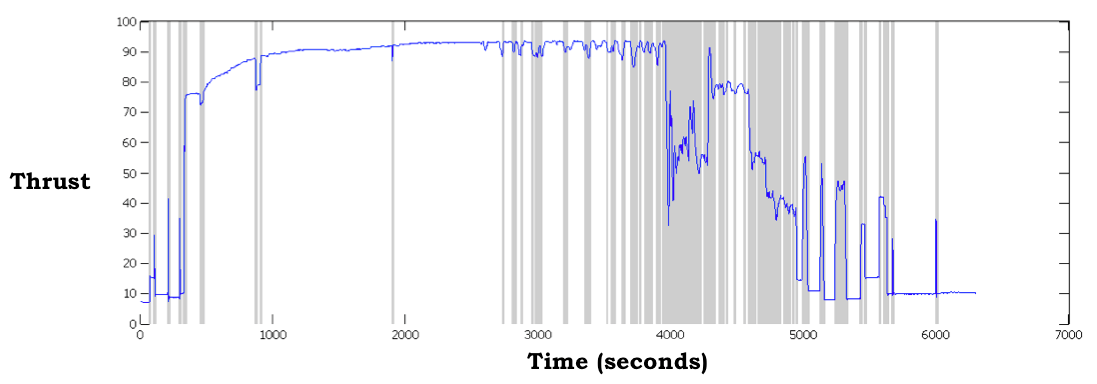

As a supplement to previous work on vibration and acoustic approaches [1], Gas Path Analysis (GPA) is the study of a gas-turbine jet engine’s temperature, pressure, and rotational parameters with the aim of detecting and diagnosing problems that may occur during flight (see Figure 1), commonly known as the field of Prognostics and Health Management (PHM). General applications of GPA for steady-state engine operation have been used successfully for over two decades in a limited capacity, due to the technological restrictions of on-board computing, costly transmission capabilities, and a lack of comprehensive analysis tools. While this foundational problem is slowly being addressed, even fewer answers exist to the question of whether GPA can be used for the immediate recognition and identification of faults that may occur during engine transients (non-steady-state regions of operation, shown in gray in Figure 2). Our research aims to explore this problem in order to build real-time tools that improve the maintenance workflow and to help develop the next generation of “intelligent engines.”

Main Ideas

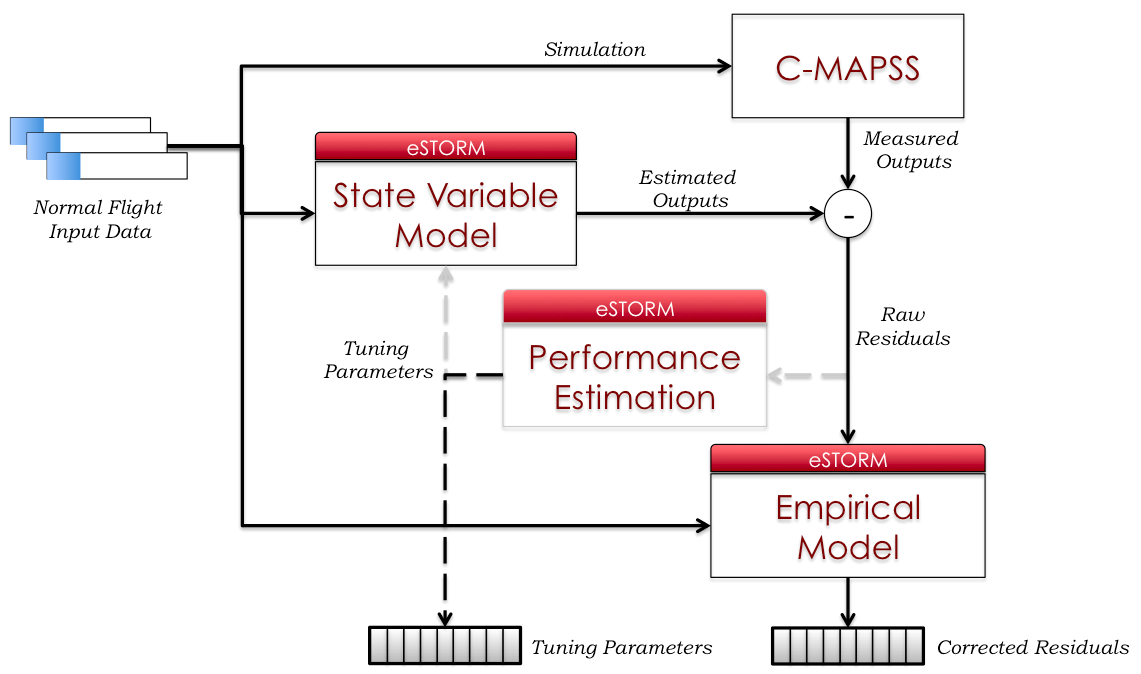

Using a variety of data created using the state-of-the-art Commercial Modular Aero-Propulsion System Simulation (C-MAPSS) [2, 3, 5], we propose a contextualized combination of state variable and empirical models for the purposes of feature extraction [4], coupled with a machine learning framework for the detection and identification of faults. In essence, we hope to use existing normal (non-fault) signatures of GPA parameters at steady-state as a reference for transient points of operation, in the hopes of finding and classifying abnormal behavior. Figure 3 outlines the feature extraction process currently being developed, which uses a state variable and empirical model of an engine to successively approximate the measured steady-state gas-path outputs, yielding tuning parameters and corrected residuals as features.

Innovations

Our work is unique for two reasons:

- No other research has used the C-MAPSS software to generate simulated flight data with this level of realism. We hope to perform validation of the C-MAPSS software with respect to data taken from actual flights, which will further solidify the merits of performing this type of analysis.

- No other research to date has focused on the problem of transient fault detection from GPA parameters.

Future Challenges

In the future, we hope to address the ongoing challenges characteristic of developing tools for airplane component Prognostis and Health Management (PHM):

- Low computational and storage complexity, allowing for real-time implementation

- Extensions to lower sampling frequency systems

- FAA certification allowing for the interaction of monitoring and control software on the plane

References

- [1] A. Geib, C.-C. Kuo, M. Gawecki, E.-S. Tsau, J. Kang, “MFCC and CELP to Detect Engine Faults,” U.S. Patent PA-0014206, Review in Progress.

- [2] Yuan Liu, Dean K. Frederick, Jonathan A. DeCastro, Jonathan S. Litt, William W. Chan. “User’s Guide for the Commercial Modular Aero-Propulsion System Simulation (C-MAPSS), Version 2,” NASA/TM 2012-217432.

- [3] Jefferey Armstrong. “Transient Test Case Generator, User’s Manual,” NASA Glenn Research Center / ASRC Aerospace Corporation, January 2010.

- [4] Al Volponi, Tom Brotherton, Rob Luppold. “Empirical Tuning of an On Board Gas Turbine Engine Model for Real-Time Performance Estimation.” Journal of Engineering for Gas Turbines and Power, ASME. March 2008.

- [5] James (Yuan) Lin, “Commercial Modular Aero-Propulsion System Simulation 40k,” 3rd NASA GRC Propulsion Control and Diagnostics Workshop, 2012